04 Jul 2024

Optimizing Energy Consumption of HVAC Systems in Commercial and Industrial Settings is vital

Optimizing the energy consumption of HVAC systems in commercial and industrial environments is not only an operational necessity, but a critical component of overall sustainability efforts.

blogAbstractMinutes

blogAbstractTimeReading

Cross Industry

AI

contact

share

Optimizing Energy Consumption of HVAC Systems in Commercial and Industrial Settings is vital.

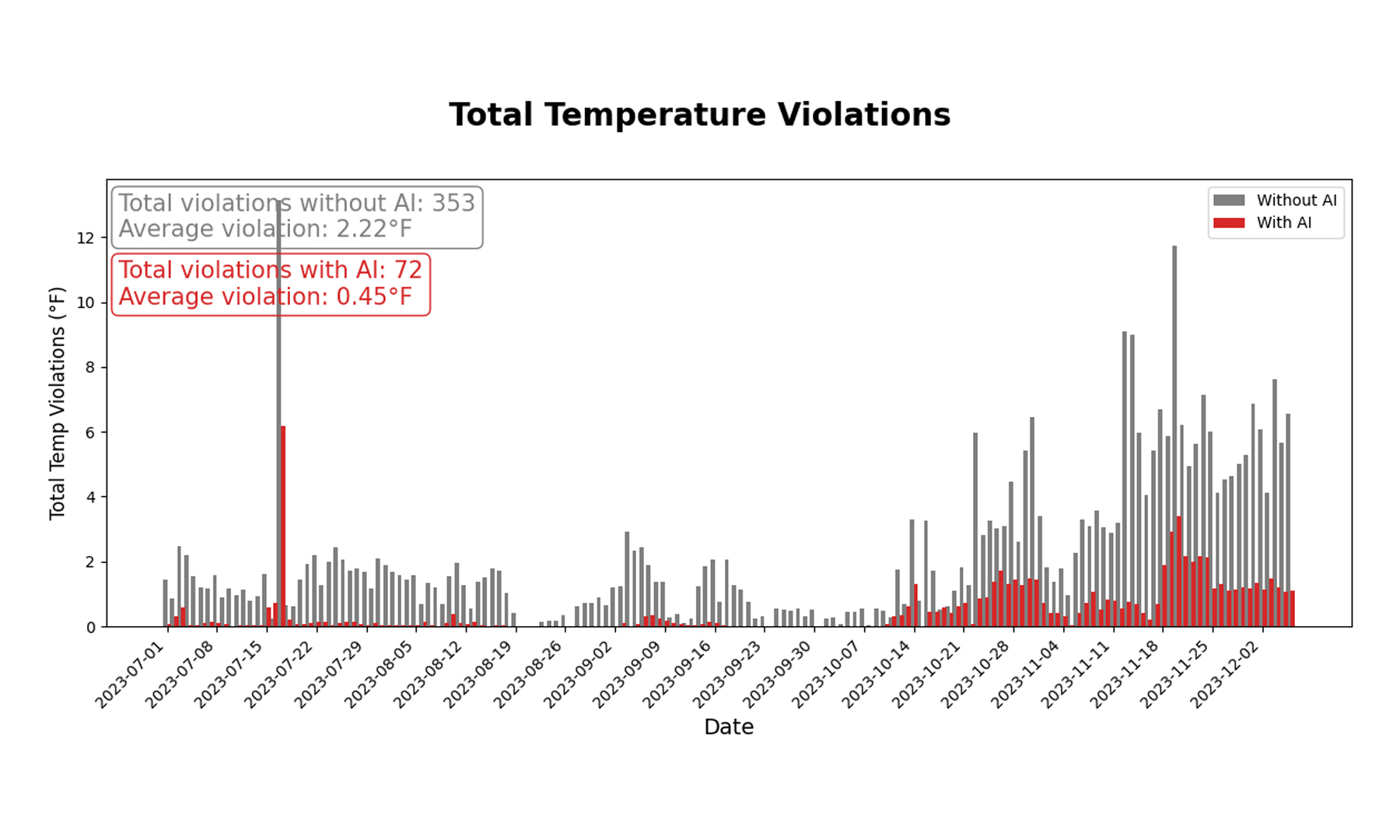

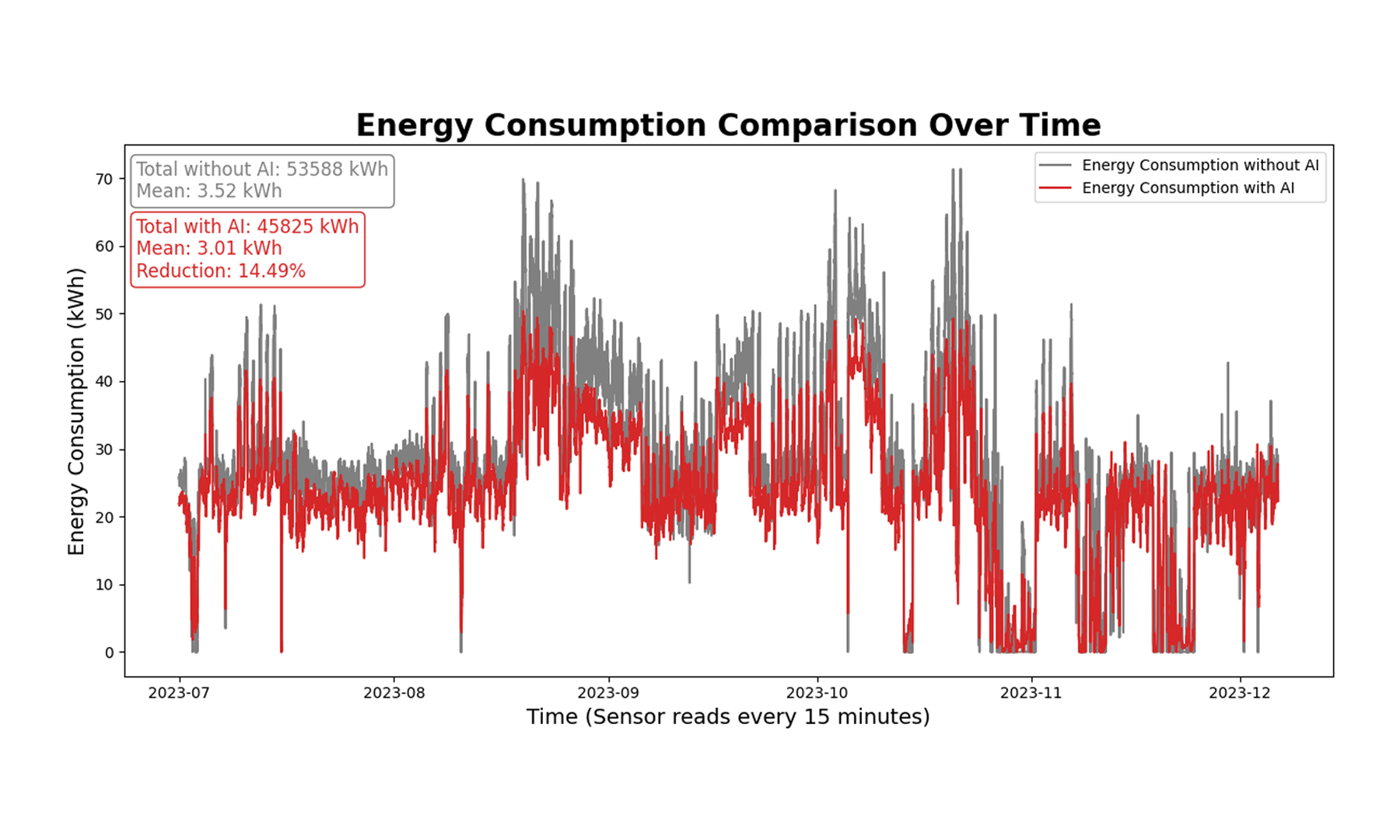

HVAC systems are major energy consumers, often accounting for up to 40% of total building energy usage. Efficient HVAC operation not only reduces energy costs but also significantly contributes to reducing carbon footprints, a pressing global priority.